Why Become a Machinist?

The machinist’s role is to setup advanced CNC machines and monitor the cutting conditions as the machine makes parts. As the machinist makes the parts, they inspect the parts with inspection tools and adjust the CNC parameters to achieve a conforming part that is within specifications. Below are eight reasons to become a machinist.

Indoor job, year-round work- All of the work is indoors, and most shops are climate controlled as well. There may be busy times of the year as well.

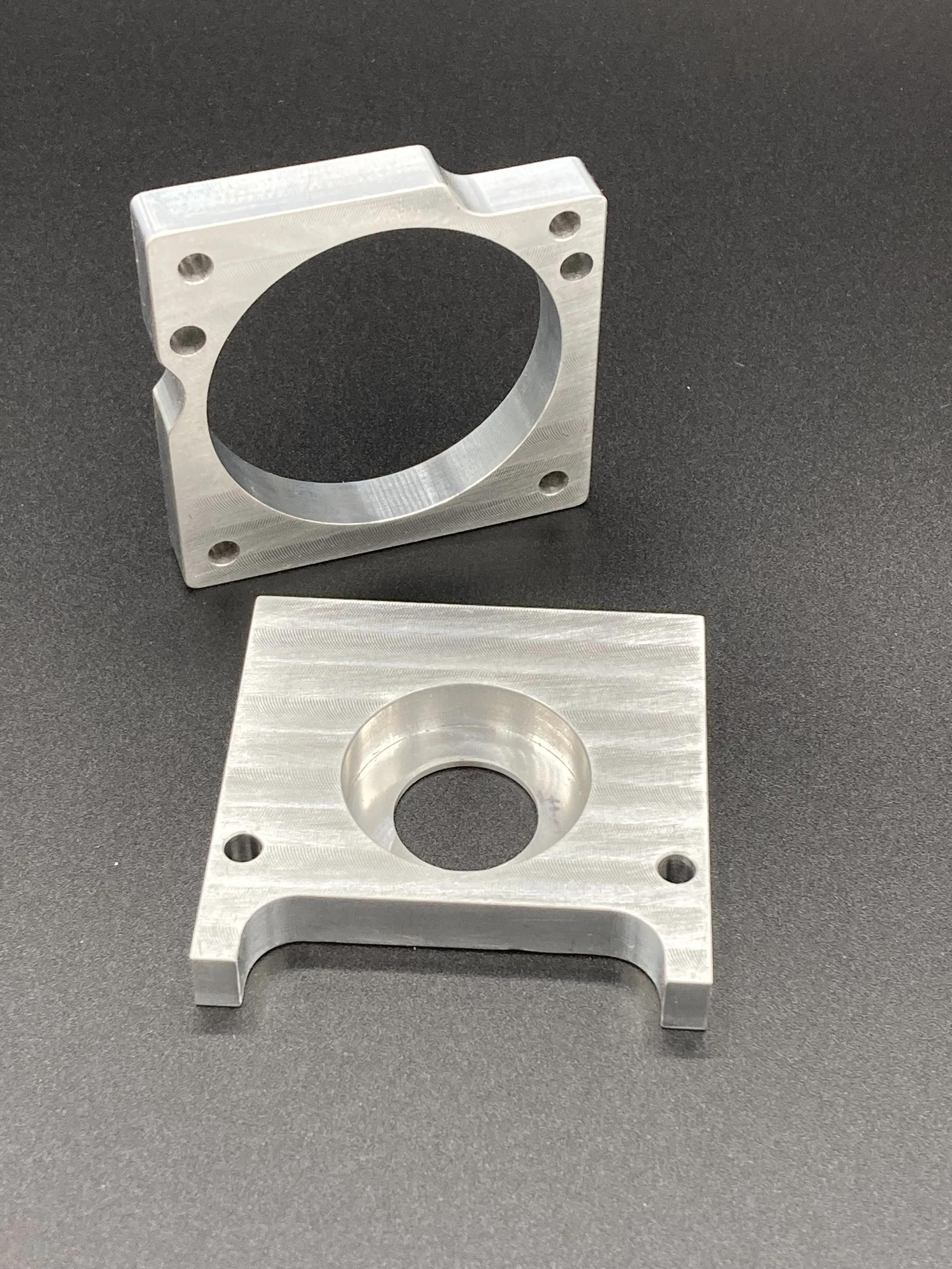

Challenging work – From operating a multi-axis CNC machine to running a machine with challenging parts, there are many challenges in the machining industry.

Work with your hands – Machining can be a cross between working with your mind and working with your hands.

Use Your mechanical skillset – In CNC machining the machinist sets up tooling for the machines and also sets up the work project in the machine. This requires mechanical aptitude.

Get to solve problems – As a machinist you may be asked to make the job run faster or more accurate. This requires problem solving abilities to figure out and determine ways to improve the project.

Sense of accomplishment – Making complex parts on complex CNC machines can be a challenging and rewarding job. There may be a sense of accomplishment when you completed a project.

Utilize advanced technology – The machines of today are very specialized and advanced. They may have many axis of linear motion and be complex to program.

Doesn’t require a four-year degree – A new career path in machining can be achieved by on-the-job training or through an associate degree program at a technical college.

To be a machinist it helps to have above average math skills as this can help in various technical situations. These math skills may help in troubleshooting, analysis, and to figure out cutting conditions of the CNC machines. Another skill to have is the ability to manage stressful situations. There may be times that may be stressful as it relates to the job at hand and having the ability to let go of stress would be a skill that is needed.