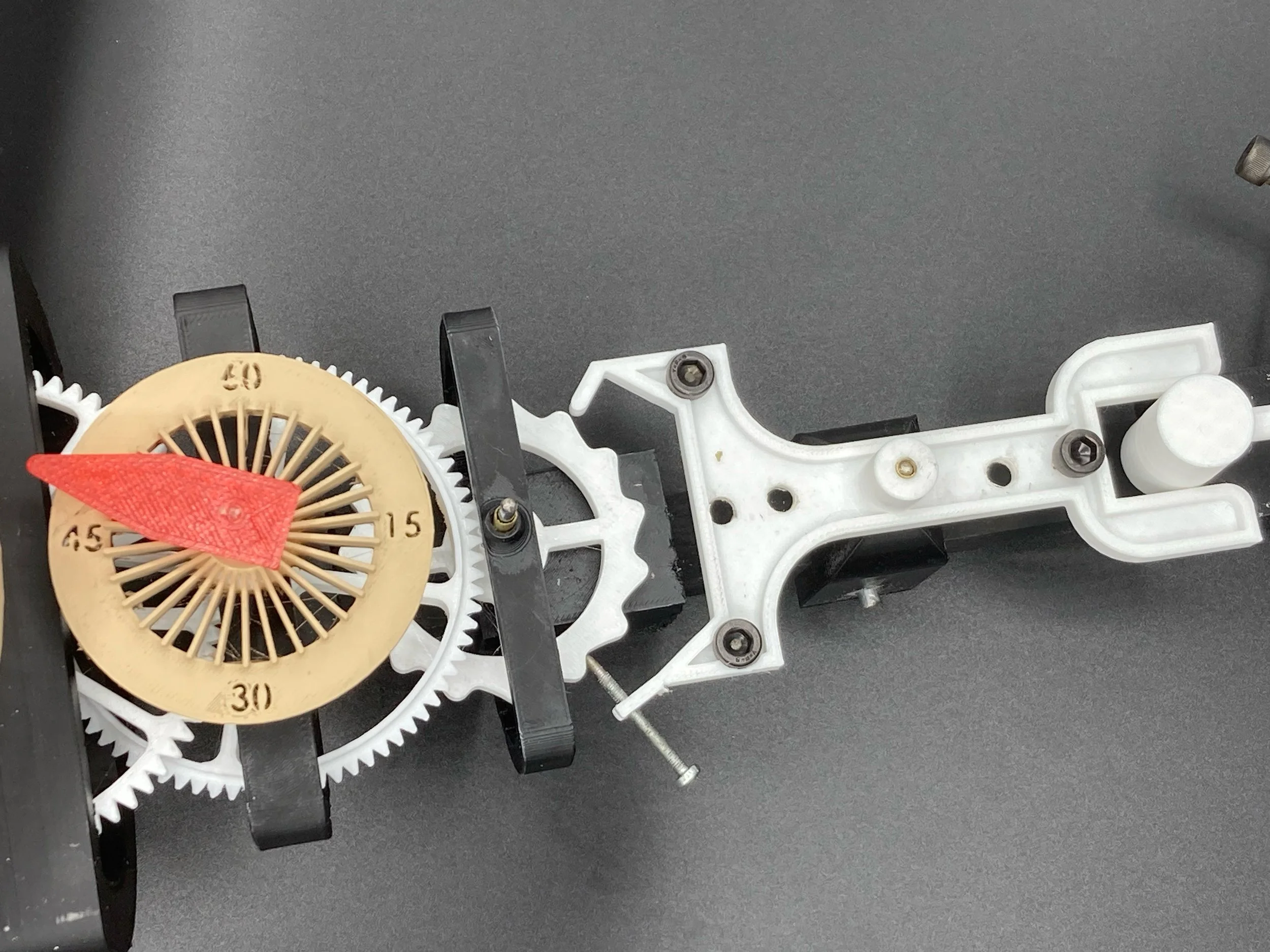

During my time operating the Machining Blog business, I have visited a few schools. I noticed one thing that was the same about their programs, and that was their 3D printers were just used to produce trinkets and not mechanical parts. I decided to create a project that could create many learning opportunities from it, and that project was to design and build a mechanical clock. The clock that I designed was based on a mechanical watch design, but I scaled the part size up by six times their actual size. I started the project by reading books on watch design and by taking apart watch movements. I learned along the way and then started designing watch movement parts in Solidworks CAD software. I then purchased a small 3D printer and started printing the parts. Once the gears started to mesh properly, I built a few prototypes along the way. With all my time that I invested in the project, it probably amounted to a couple thousand hours. The result was a clock that is pretty accurate for being printed, not machined.

Machining.Blog® is a weekly blog focused on manufacturing career development. It features blog articles on the fundamentals of manufacturing for aspiring machinists. Our goal is to create an interest in manufacturing in the USA. Our writer Matthew Schowalter has worked in manufacturing for 24 years, and he covers the topics that matter to someone starting their career in manufacturing.

“The soft skills the machinist uses are the unseen tools in their box and can directly impact the success or failure of a dreamed after machining career.”