Three Key Machining Skills That Will Set You Apart

Knowing what features to inspect on machined parts, being aware of machining conditions, and what items and details to deburr can make all the difference in the success of the manufacturing project. By mastering these three items, it will set you apart as a great machinist. Let’s review in detail.

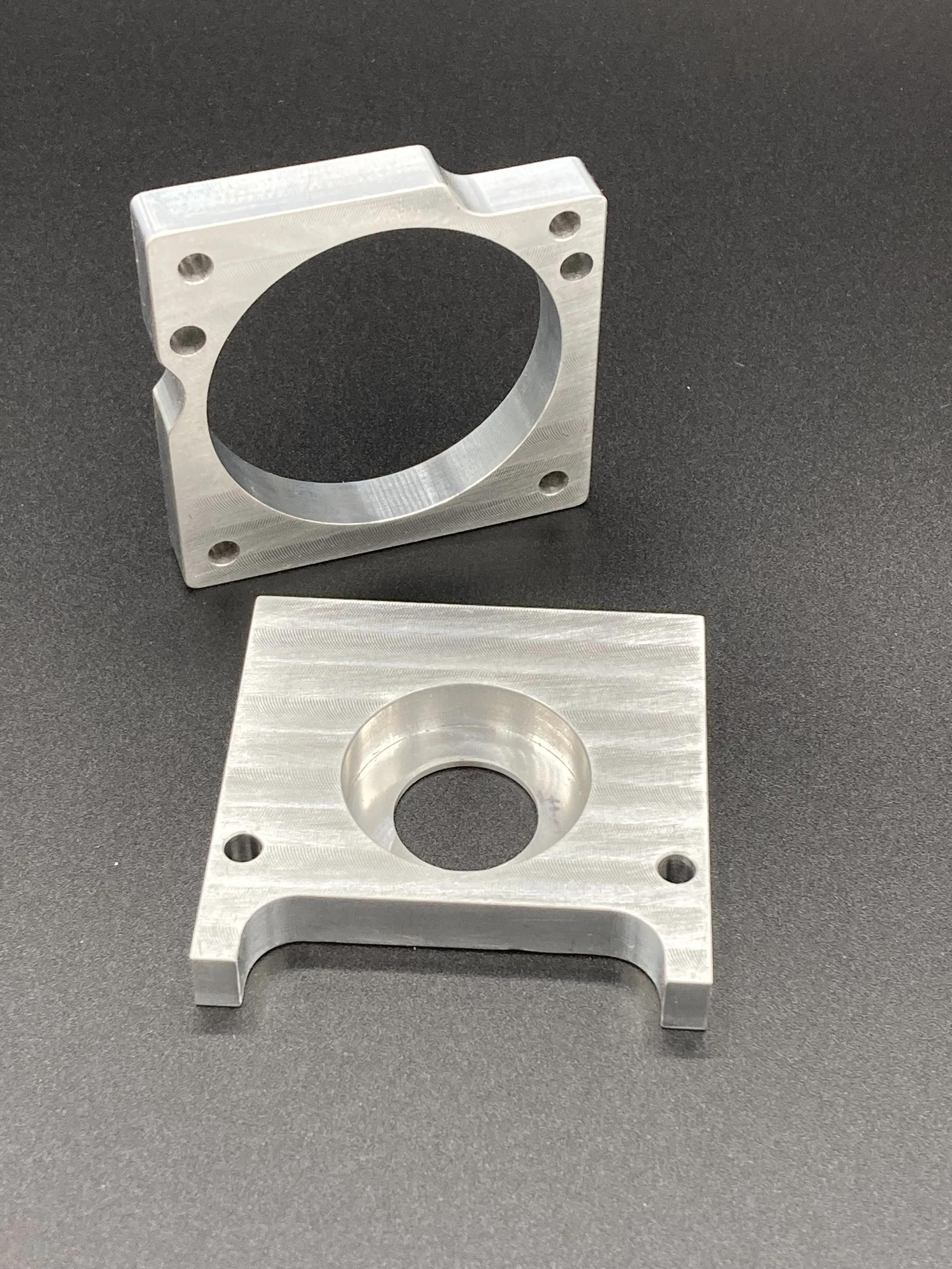

Inspection of Machined Features and Parts:

By working cross functionally with others while understanding the inspection of the parts, you will gain insight in the inspection process. Most manufacturing facilities will have documents for inspection for recording the feature dimensions, while sometimes prototype machining and machinists setting up machines will have to determine the processes of inspection. Being able to understand the CNC machining process and which features are cut by which processes will ensure success.

Awareness of Machining Conditions:

Paying attention to the details of the part features, while also observing the cutting conditions of the machine while in process will ensure success of the project. There are times when cutting tools get dull and even break, so the machine operator must be alert and paying attention to the details of the cutting operation.

Deburring the Parts Properly

Another way to look at this subject is taking responsibility for the work and craftsmanship of the work. Sometimes the features can be deburred by the CNC machine and sometimes a slight clean up deburring process may be needed to make the machined component into a quality part. Knowing what to deburr and how much to deburr is key and communicating with others on this subject can be important also.