Transitioning Into a Machining Career

A manufacturing career was not the first plan for Alex’s career, but he gave it a consideration and a try after discussing with someone close to him. This career change happened in 2017 after he spent several years working in the restaurant industry as a busboy and a line cook. From there he went to technical school for a semester for computer programming, but he cancelled that plan after trying to take nineteen credits in one semester.

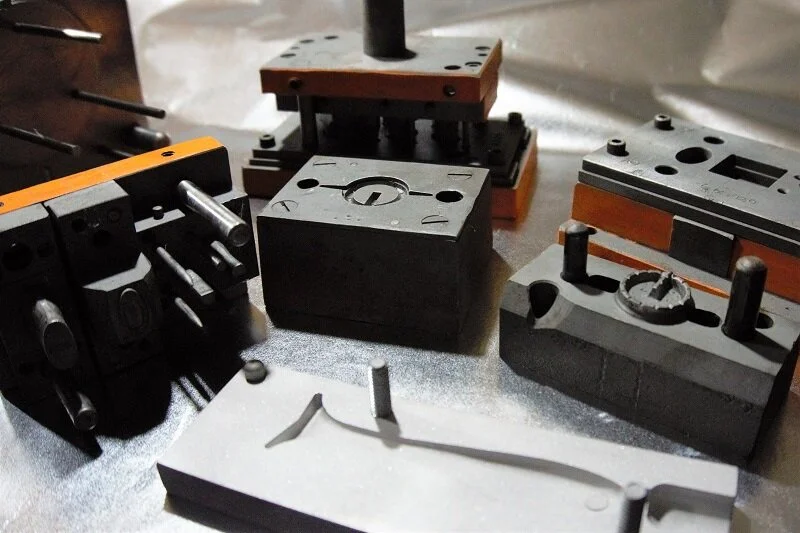

With a desire to learn about CNC machining, he applied for a job at Standard Machine in Saukville Wisconsin. He was hired as a CNC Machine Operator and quickly learned while running basic machining jobs on the CNC equipment. In his first year of machining, he gained experience on the Fanuc 3-axis mill, the 3-axis CNC lathes and the swiss lathes. In addition to that he learned how to do tool offsets and work offsets on the lathes and mills.

Alex now has a basic knowledge in CNC program editing. With this knowledge he may be able to look in the CNC program to fix the machining issue. To aid in the circumstances that could be stressful, he looks at his job as having small individual goals, that add up to a large goal. He fully understands that its always better to make fewer machined parts well, versus lots of bad machined parts.

Alex plans on staying with the career path that he is on right now. He understands that this career is challenging. With enough time he will have a greater understanding of machining and a great career.