Implementing a Cobot in a School Program

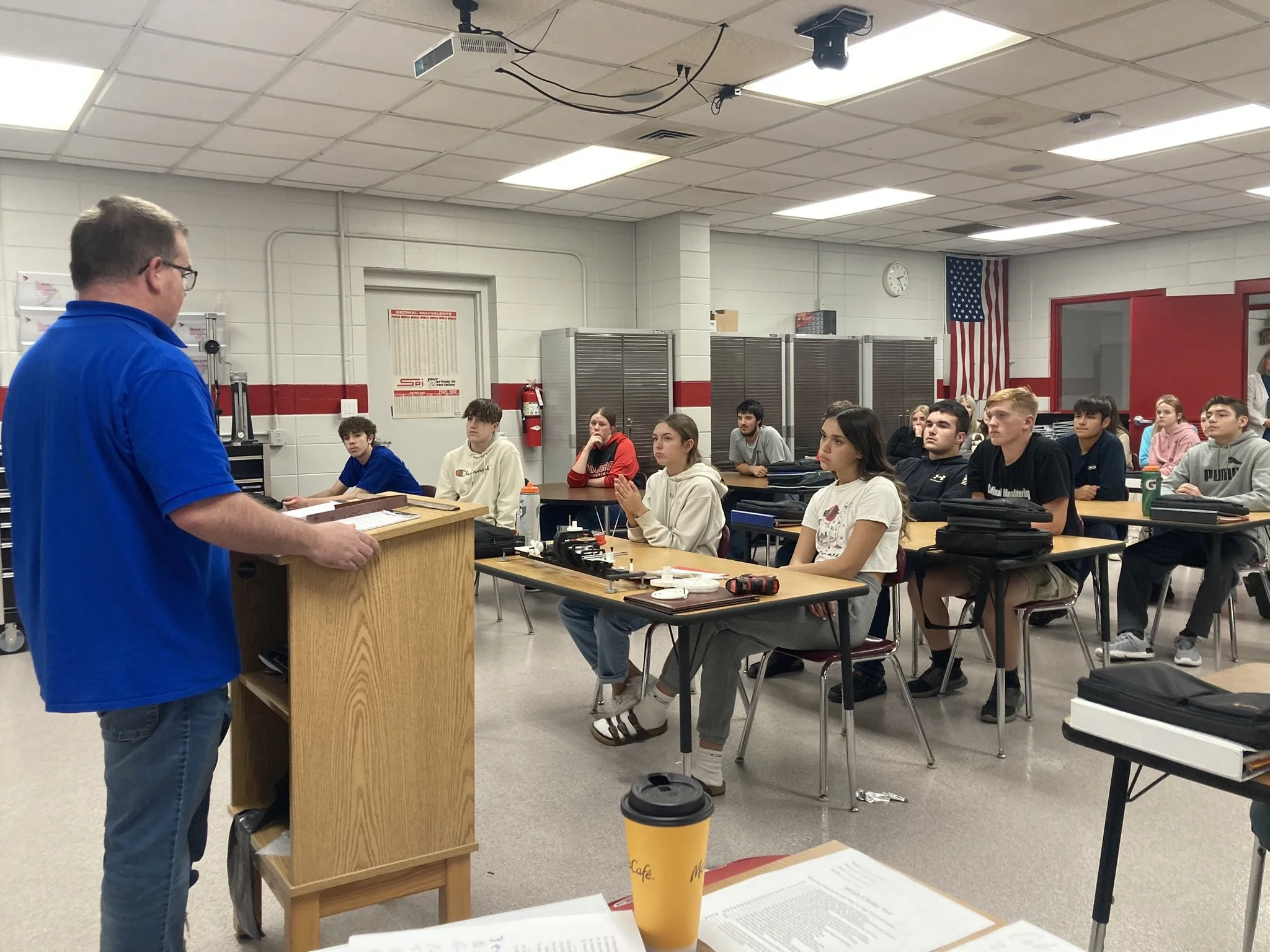

Tiger Manufacturing is a school based business in Webster High School in Webster Wisconsin. It is a business run inside the schools technical education program. The program is run by the teacher Roy Ward. I asked Roy a few questions about the program and the implementation of the cobot on the CNC lathe.

What led to the decision to add a cobot for the lathe to the school program?

We have a student school based business called Tiger Manufacturing. One of parts volume and was high and seemed like a natural fit for investing in a robot.

Was industry involved in the implantation of it?

Yes, we so thankful for several industry partners who made this possible. Without McNally Industries, we wouldn't have pursued the robot. They believed in us and have been sending us work to machine. The robot was purchased through Dan Carney of PCC. He along with Darren helped acquire, setup, program, and train. Nexen a manufacturing company in Webster sent several guys for many days to integrate the old Okuma CNC lathe with the new technology of the UR robot. All of this work was given at no cost to Tiger Mfg. All of these partners continue to support our students/program.

Do you teach the programming and setup of it?

Yes, we teach programming of the robot as well as CNC machines. UR has an online academy with some great intro lessons.

While watching the cobot video, I saw how this can greatly influence students, now a robot can do the tedious work, and the student can setup and program it, How has this cobot affected the students and curriculum?

It gives students an opportunity to see first hand real life automation. Some students are interested and others could care less. We are all wired differently. For some, this could be life changing. You don't know if you've never been exposed. I like that students have it available and can really dive in. There are so many learning experiences. Even if we didn't have a product in mind, I think it is great that they have this technology to learn to use. It isn't intimidating and it almost feels as if you are playing a game. Students pick up the programming very quickly.

Are there any other planned uses for the cobot in the shop?

We'd like to see another class be taught more specifically to robotic programming. In Tiger Mfg, we program when there is a need. We will look to make our program more efficient and stage parts for longer runs. We are also considering what other parts we could use the robot to collaboratively make. We also have the robot on a stand and wired to be able to be moved to another CNC machine if needed.

Do you have any recommendations for other high schools who want to implement this technology?

I'd say go for it. From what I have read, more and more manufacturing companies are going to need to embrace this technology. There are good paying jobs in automation. You'll find students who will love using the robot. Even if you don't have a part in mind, you'll see all sorts of opportunities once you have it. It is a neat piece of technology for teaching problem solving and engineering. You can always look to improve. A lot of tasks have to be figured out since each application is so unique. You can't just go to the hardware store and buy a way to hold a part with the robot so you design and 3D print a gripper. Same is true about material staging, programming, etc...