All in Technical Education

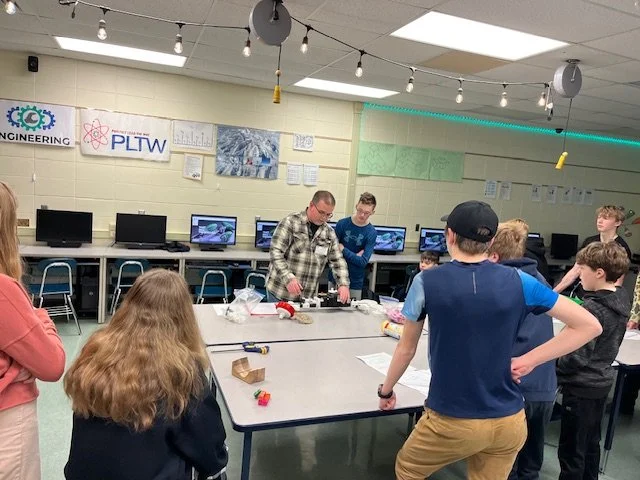

I gave a classroom presentation in two engineering classes within the technical education department at a local middle school. The students were engaged in the mechanical clock presentation and asked me great questions.

Across the country, educators are searching for meaningful ways to prepare students for life after high school. At Cardinal Manufacturing in Strum, Wisconsin, that preparation is at the core of their mission. The program’s primary goal is to equip students with the technical skills, confidence, and strong work habits that employers look for, such as professionalism, communication and responsibility.

Cardinal Manufacturing in the Eleva-Strum School District in Wisconsin is a student-run manufacturing business that has repair services, welding services, woodworking services, machining services, design services, and 3D printing services.

I recently had an opportunity to work with the technical education program at Eleva-Strum School District in Wisconsin. The project that I had for the students was to modify a few parts for a mechanical clock. It was an amazing experience to be greeted at the door by a student and the student gave me a great handshake. The technical education class teaches these soft skills to the students, starting in seventh grade.

Machining and Tool & Die Making is what I have spent most of my career doing. There is something to be said for being able to turn a raw piece of material into a complex finished part. Through all my roles in the machine shop environment, I have identified a few soft skills, hard skills, and technical skills to have mastered if you want to be a great machinist.

A few years ago, I learned about the Cardinal Manufacturing business in Eleva-Strum High School in Wisconsin. I was invited to attend their workshop on how they built their program in their technical education department. It was such an inspiration to hear how engaged the students were and how they were learning solid employability skills.

Cardinal Manufacturing is a student-run business in the Eleva-Strum High School. In a student-run business the students are responsible for all aspects of the business. It is a custom job shop that makes machined parts for community members and people throughout the country. Check out this video on the program.

Nestled in Eleva-Strum High School, Cardinal Manufacturing is revolutionizing technical education through its student-run business model. As a beacon of excellence, Cardinal Manufacturing in Strum, Wisconsin empowers students to gain hands-on experience in manufacturing while running a real business. This innovative approach not only equips students with invaluable skills but also positions the program as a leader in the technical education world.

The community support of the technical education program at Eleva Strum High School is impressively large and there are several reasons why. The technical education program operates as a student-run business that fabricates and machines parts for customers. The business is called Cardinal Manufacturing. The money made by the business is used to buy raw materials, upgrade equipment, marketing, cover the operating costs, and to pay the student employees.

I recently had an opportunity to visit the technical education department at the Eleva-Strum high school. While I was in the shop, there was an eighth-grade class working on manual milling projects, sheet metal projects, welding projects, and brazing projects. These projects that they were making teach the students the fundamental principles of manufacturing. With this class, the students spend six days in each subject area, then they switch to another project. They learn the basics like how to read a tape measure, and how to use a dial caliper.

This book is an insight into how to start a student-run business in your school district. It offers a look inside Cardinal Manufacturing in the Eleva-Strum School District. It defines what a student-run business is and lists the benefits of a program like this. Check it out!

Spartan Manufacturing in the School District of Superior Wisconsin is on a mission to expose students to industry and the trades in their area, and to better represent all the post high school options available to students at Superior High School. They want to remove the stigma of a two-year technical degree or an apprenticeship program.

How we are taught how to pronounce a measurement in mathematics class is different from how we pronounce a measurement in machine shop class. In the following chart, I will break down the decimal place pronunciation of 0.123456.

While recently attending a workshop on starting or growing your school-based enterprise at the school district of Eleva-Strum in Wisconsin I discovered that they have great model for their student-run business. Their program, Cardinal Manufacturing teaches soft skills and employability skills along with learning the technology.

The Red Raider Manufacturing program in the Sheboygan Area School District had 1,090 students in the 2021-22 school year. Its mission is to give all SASD students access to the most up-to-date, relevant and exciting learning experience to succeed. The vision of the program is education and industry partnering to turn a manufacturing/technical career into an aspiration. The students in the program are high achieving, proud of what they do, and career ready.