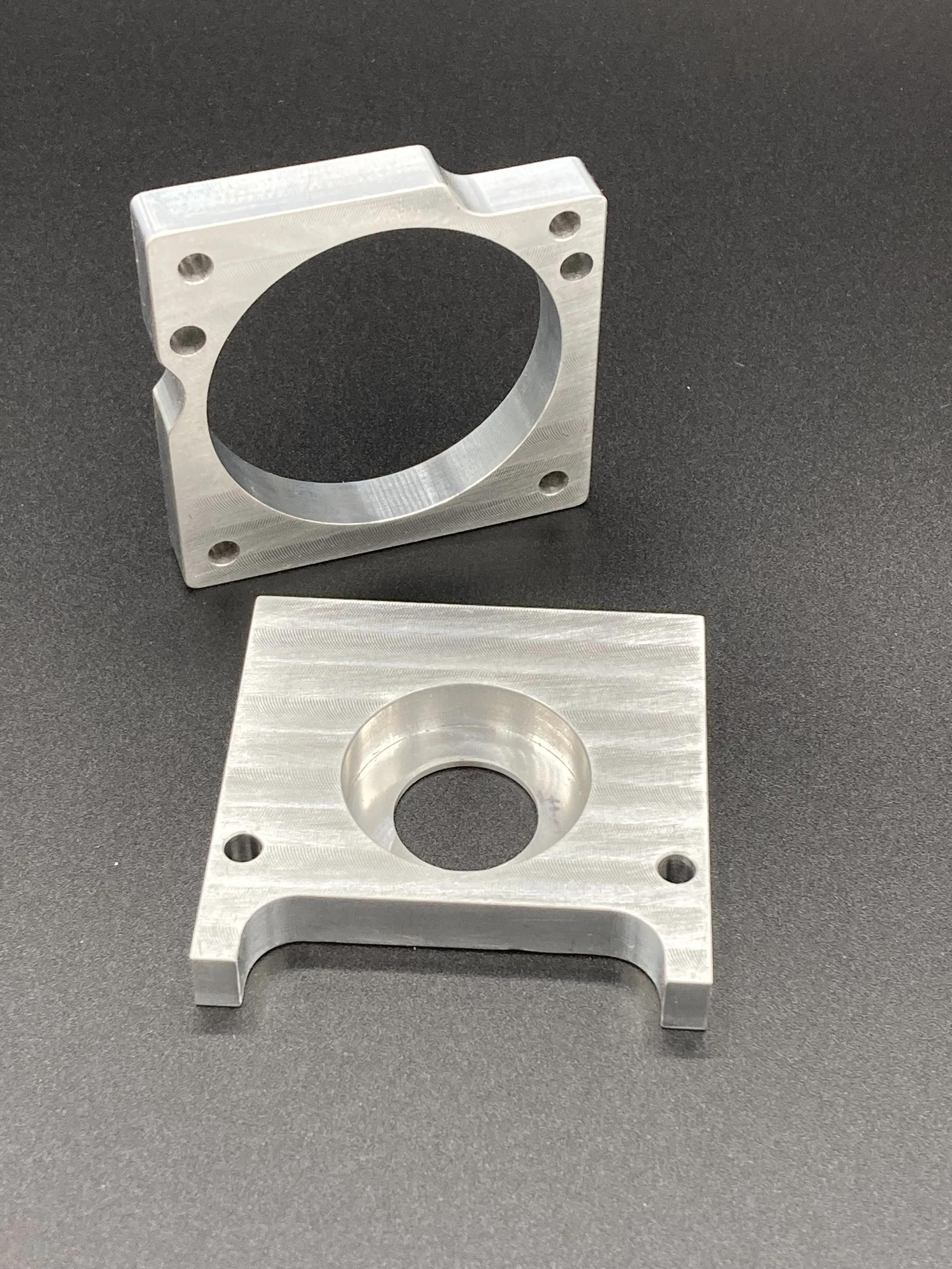

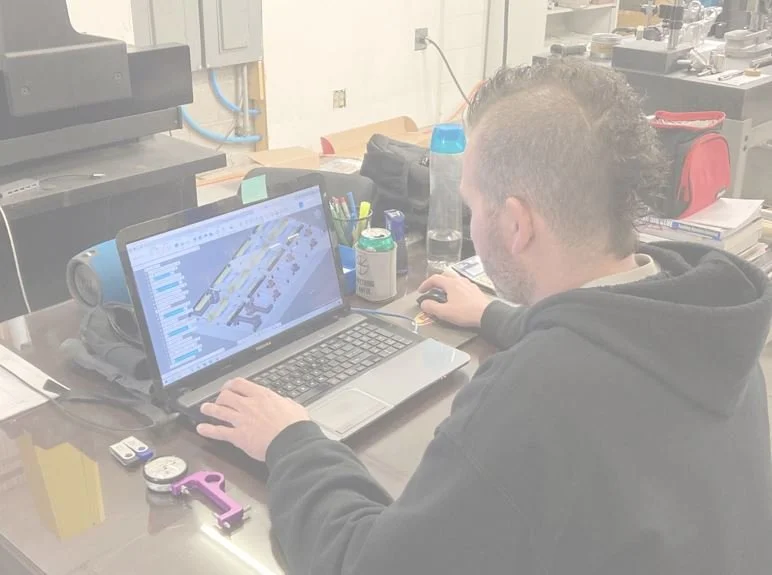

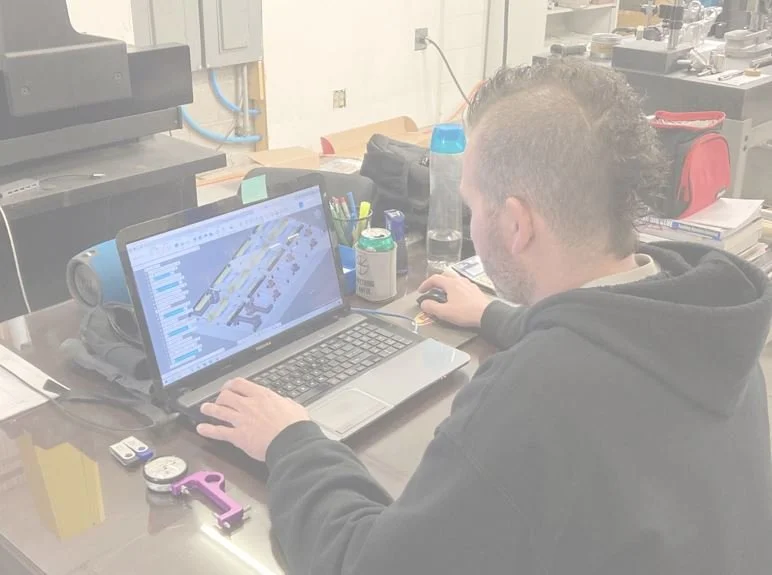

CNC milling offers precise and flexible solutions for manufacturing. Beyond operating the machine, producing parts demands solid design skills, technical knowledge, and effective process management.

This article outlines the key steps in making a CNC-milled part, detailing the process from concept to finished product.