All tagged CNC Programming Basics

Each line of code in a CNC program is called a “Block”. It contains G and M codes in it.

The block cannot have two M-codes in it

The ending of a Block has a End-of-Block symbol and it is a semi-colon. (Example: G1X.5; )

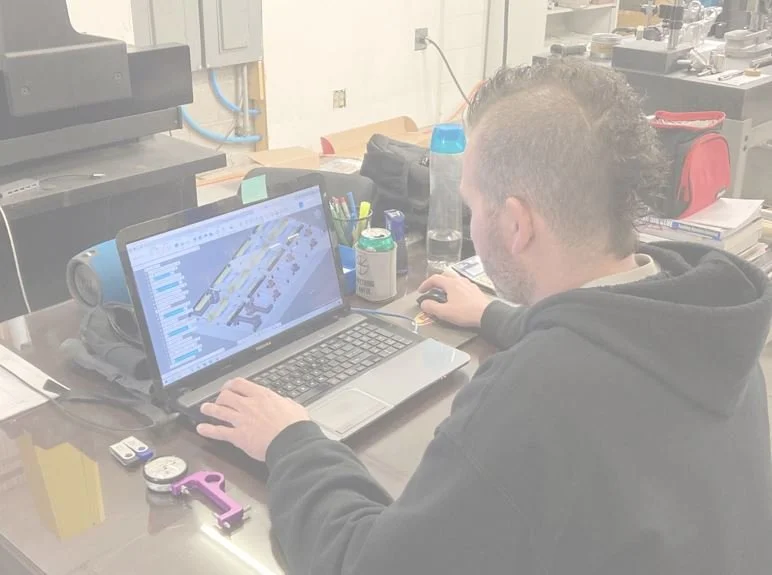

When planning a CNC machining process there are many considerations and options to choose. From cutting tool selection to cutting parameters, the choices have a major effect on the end results. Here is what it might take to define a CNC toolpath:

I recently had an opportunity to interview Phil Brown and Umair Riyas from NexGenCAM about how to begin a career in computer-aided manufacturing or CAM. They are applications engineers that specialize in CAM software. Phil and Umair have extensive backgrounds in CNC and CAM/CAD, they offer a few tips to others who may be interested in starting a career in the field.

Standard G-Codes for CNC Lathes

G0 - Rapid Movement

G1 - Linear Feed Movement

G2 - Clockwise Interpolation - Circular Movement

G3 - Counter Clockwise Interpolation - Circular Movement

G4 - Dwell

G9 - Exact Stop

G10 - Set Data

G17 - XY Machine Plane Selection