CNC Lathe G Code Programming

Standard G-Codes for CNC Lathes

G0 - Rapid Movement

G1 - Linear Feed Movement

G2 - Clockwise Interpolation - Circular Movement

G3 - Counter Clockwise Interpolation - Circular Movement

G4 - Dwell

G9 - Exact Stop

G10 - Set Data

G17 - XY Machine Plane Selection

G18 - ZX Machine Plane Selection

G19 - YZ Machine Plane Selection

G20 - Machine is Programmed in Inches

G21 - Machine is Programmed in Millimeters

G28 - Return Home (First Reference Position)

G30 - Return to the Second Reference Position

G40 - Cancel the Turning Tool Nose Radius Compensation

G41 - Turning Tool Nose Radius Compensation - Left

G42 - Turning Tool Nose Radius Compensation - Right

G50 - Maximum Spindle Speed Limit

G52 - Local Coordinate System Setting

G53 - Machine Coordinate System Setting

G54 - Work Offset / Work Coordinate System

G55 - Work Offset / Work Coordinate System

G56 - Work Offset / Work Coordinate System

G57 - Work Offset / Work Coordinate System

G58 - Work Offset / Work Coordinate System

G59 - Work Offset / Work Coordinate System

G80 - Cancel a Canned Cycle

G81 - Drilling Canned Cycle

G82 - Drilling Canned Cycle

G83 - Peck Drilling Canned Cycle

G84 - Tapping Canned Cycle

G85 - Boring Canned Cycle

G86 - Boring Cycle

G90 - Absolute Programming

G91 - Incremental Programming

G92 - Thread Cutting Canned Cycle

G96 - Constant Surface Speed Selection

G97 - Spindle Speed Selection

G98 - Feed Rate Per Minute

G99 - Feed Rate Per Revolution

Standard M-Codes for CNC Lathes

M0 - Machine Stop / Program Stop

M1 - Optional Stop (There is a button on the controller that allows the program to stop at this point)

M2 - End of Program

M3 - Spindle Rotation Counter Clockwise / Spindle Start

M4 - Spindle Rotation Clockwise / Spindle Start

M8 - Coolant On (There are normally more coolant codes)

M9 - Coolant Off

M10 - Chuck Clamp

M11 - Chuck Unclamp

M17 - Turret Rotation Forward

M18 - Turret Rotation Reverse

M19 - Orientate the Spindle

M30 - End of the Program / Reset the Program

M36 - Parts Catcher Extend, On

M37 - Parts Catcher Retract, Off

M98 - Subprogram Call, Jump-to

M99 - Subprogram End

Terms To Understand

M - Codes - Miscellaneous CNC function programming in the standard G-Code programming format. The M-codes vary by the machine tool builder

Modal - A term that means that two G-Codes from the same group cannot be executed on the same line of code, or at the same time.

The Order of a CNC Program

The Program Number

A Tool Change Call

Define a Tool Length Offset Number

Define a Work Coordinate System Number

Tool Path Code

Axis Zero Return

End of the Program

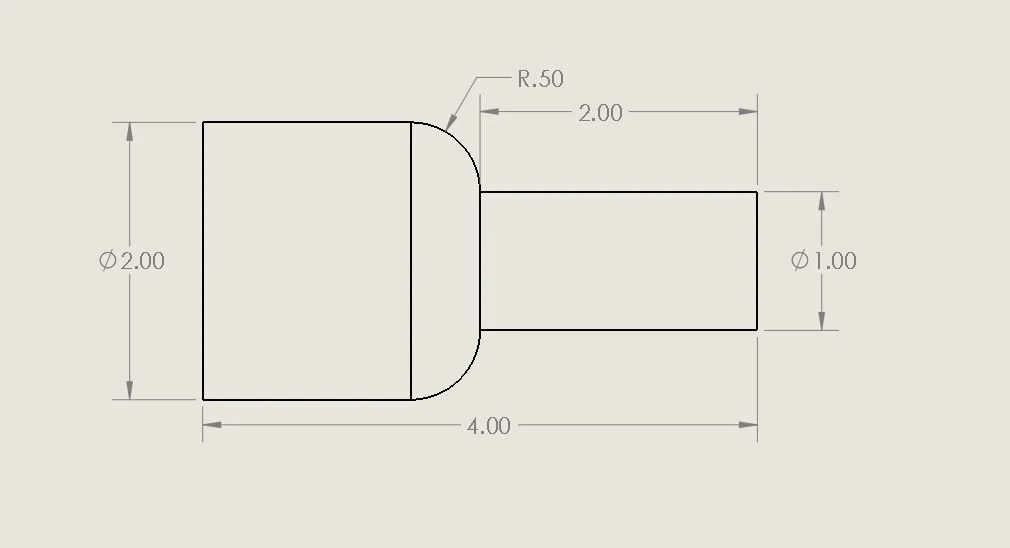

FACING THE PART - G CODE PROGRAM

%

O0010 (PROGRAM NUMBER)

(LATHE PART)

G50S3000 (MAXIMUM SPINDLE SPEED)

T0101 (TOOL CALL, TOOL OFFSET CALL)

G96S1500M3 (CONSTANT SURFACE SPEED, TURN SPINDLE ON AT 1500RPM)

(FACING OPERATION)

G0G54G90X1.85Z0.0M8 ( G54 WORK COORDINATE, RAPID TO X1.85, Z0, COOLANT ON)

G1G99X0.0F.003 (FACE PART TO X0.0)

G0Z.100 (RAPID TO Z.1)

G0X2.0 (RAPID TO X2.0)

G0X6.5M9 (RAPID TO X 6.5, COOLANT OFF)

M30 (END OF PROGRAM)

%

Turning The Outside Diameter - G Code Program

%

O0011 (PROGRAM NUMBER)

(LATHE PART)

G50S3000 (MAXIMUM SPINDLE SPEED)

T0101 (TOOL CALL, TOOL OFFSET CALL)

G96S1500M3 (CONSTANT SURFACE SPEED, TURN SPINDLE ON AT 1500RPM)

(OD TURN OPERATION)

G0G54G90X1.75Z0.05M8 (G54 WORK COORDINATE, RAPID TO X 1.75, Z.05, COOLANT ON)

G1G99Z-4.010F.006 (FINISH TURN PART)

G0X1.85 (RAPID ABOVE PART)

G0Z.1 (RAPID TO Z.1)

G0X6.5M9 (RAPID TO X6.5, COOLANT OFF)

M30 (END OF PROGRAM)

%