Essential Tools Every Machinist Should Own (and why)

In the world of machining, precision isn’t just a goal, it’s the foundation of the craft. Whether you’re working in a high-tech CNC shop or tinkering in a home garage, the right tools are the difference between a flawless part and a costly mistake. But with so many gadgets and gizmos on the market, how do you know which ones are truly essential?

This guide breaks down the must-have measuring, cutting, and setup tools every machinist should own, and—more importantly—why they matter.

1. Measuring Tools: The Language of Precision

If machining is an art, measuring tools are the vocabulary. Without them, you’re working blind.

Calipers (Digital or Dial)

Your go to for quick, accurate measurements of inside, outside, and depth dimensions. Digital calipers are fast and easy to read, while dial calipers offer reliability without batteries.

Micrometers

For when you need accuracy down to the thousandth of an inch. A good set includes outside, inside, and depth micrometers.

Dial Test Indicator

Essential for aligning workpieces, checking runout, and ensuring setups are dead-on.

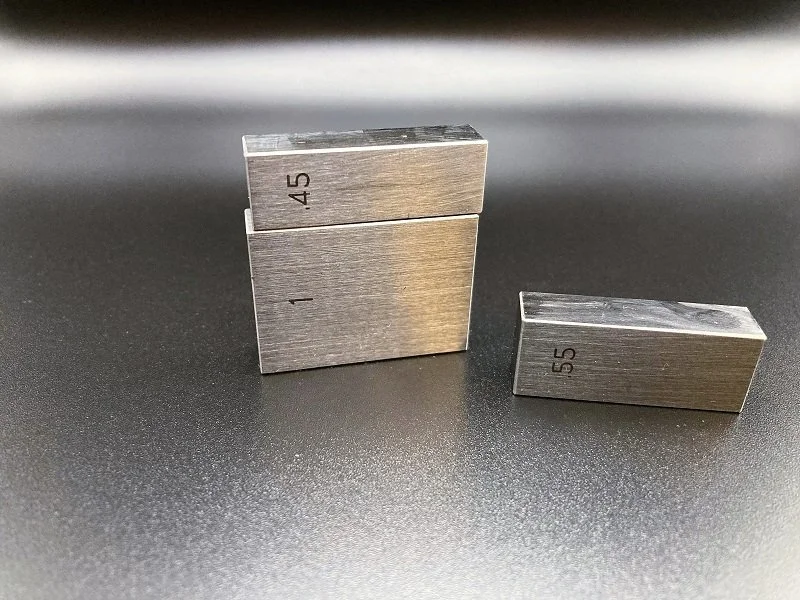

Gauge Blocks

The gold standard for calibration and precision reference.

Pro Tip: Always store measuring tools in a clean, dry place because precision instruments are only as good as their condition.

2. Cutting Tools: Where the Magic Happens

Cutting tools are the hands of the machinist—they shape raw material into finished parts.

End Mills

A variety of sizes and coatings will cover most jobs. Keep them sharp for cleaner cuts and longer tool life.

· Drill Bits

For drilling holes in parts. Common drills are made from high speed steel (HSS), colbalt, and carbide.

Lathe Tooling

Includes carbide inserts for turning, facing, and threading.

Boring Bars

For enlarging and finishing holes with precision.

Parting Tools

Used to cut off finished parts or separate sections of material cleanly.

3. Setup Tools: The Unsung Heroes

A perfect cut starts with a perfect setup. These tools ensure your workpiece is positioned and held securely.

Vise & Clamps

A sturdy machinist vise is a must for milling, while clamps and step blocks secure irregular shapes.

Parallels

Keep workpieces level and at the correct height in the vise.

Edge Finder

Helps locate the exact position of your workpiece relative to the machine spindle.

1-2-3 Blocks

Precision-ground blocks that serve as spacers, setup aids, and measurement references.

Why These Tools Matter

Machining is a game of consistency and repeatability. The right tools:

Save Time by reducing setup errors and rework.

Improve Accuracy so parts meet tight tolerances.

Extend Tool Life by ensuring proper alignment and cutting conditions.

Boost Safety by keeping workpieces secure and predictable.

Final Thoughts

A machinist’s toolbox is more than a collection of metal and plastic, it’s a set of instruments that enable creativity, precision, and craftsmanship. While you can always add specialty tools over time, starting with these essentials will set you up for success in almost any machining project.