Inside the Shop: A Day in the Life of a Precision Machinist

The shop floor hums before the sun is fully up. The air carries a faint scent of machine oil, and the rhythmic clatter of metal on metal is already underway. For a precision machinist, the day doesn’t just begin with a clock-in, it begins with a mindset: accuracy above all else.

6:45 AM – The Quietness

The first moments in the shop are almost meditative. Tools are checked, gauges calibrated, and the day’s job orders reviewed. Each blueprint is more than a set of lines and numbers and it’s a puzzle waiting to be solved.

“Every part has a story,” says veteran machinist Matt, tightening the chuck on a CNC lathe. “Our job is to make sure it’s told exactly right.”

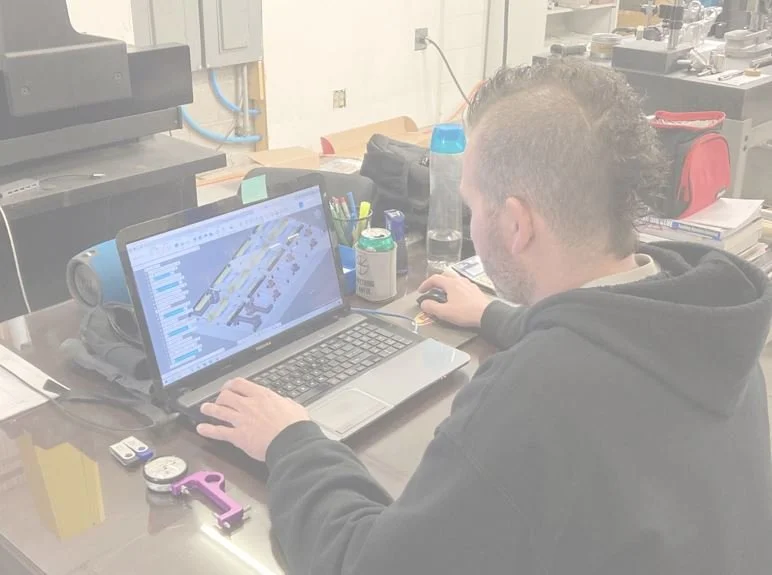

7:30 AM – From Blueprint to Reality

The morning’s first task: machining a custom aerospace component. The tolerances are unforgiving, within two thousandths of an inch, meaning even the smallest deviation could render the part useless.

The process unfolds in stages:

Programming the CNC machine with precise tool paths.

Selecting the right cutting tools for the material today, a high-strength titanium alloy.

Running a test cut to verify dimensions before committing to the full run.

Every step demands focus. A single oversight could mean hours of wasted work and thousands of dollars in scrap.

10:15 AM – The Unexpected Curveball

Mid-morning, a machine alarm interrupts the steady workflow. A cutting tool has worn down faster than expected, leaving a rough finish on the part. The machinist’s job now shifts from production to problem-solving:

Diagnose the cause, material hardness? Feed rate too high?

Replace the tool and adjust the program.

Re-run the part, double-checking every measurement.

It’s a reminder that in precision machining, adaptability is as important as skill.

12:00 PM – Lunch Among the Machines

Lunch breaks in the shop are rarely quiet. Conversations bounce between weekend fishing trips and debates over the best coolant for stainless steel. There’s camaraderie here, forged in the shared pressure of meeting deadlines without compromising quality.

1:00 PM – The Afternoon Push

The afternoon brings a different challenge: a rush order for a medical device component. The stakes are high and this part will be used in surgical equipment. The machinist moves with deliberate speed, balancing urgency with the need for flawless execution.

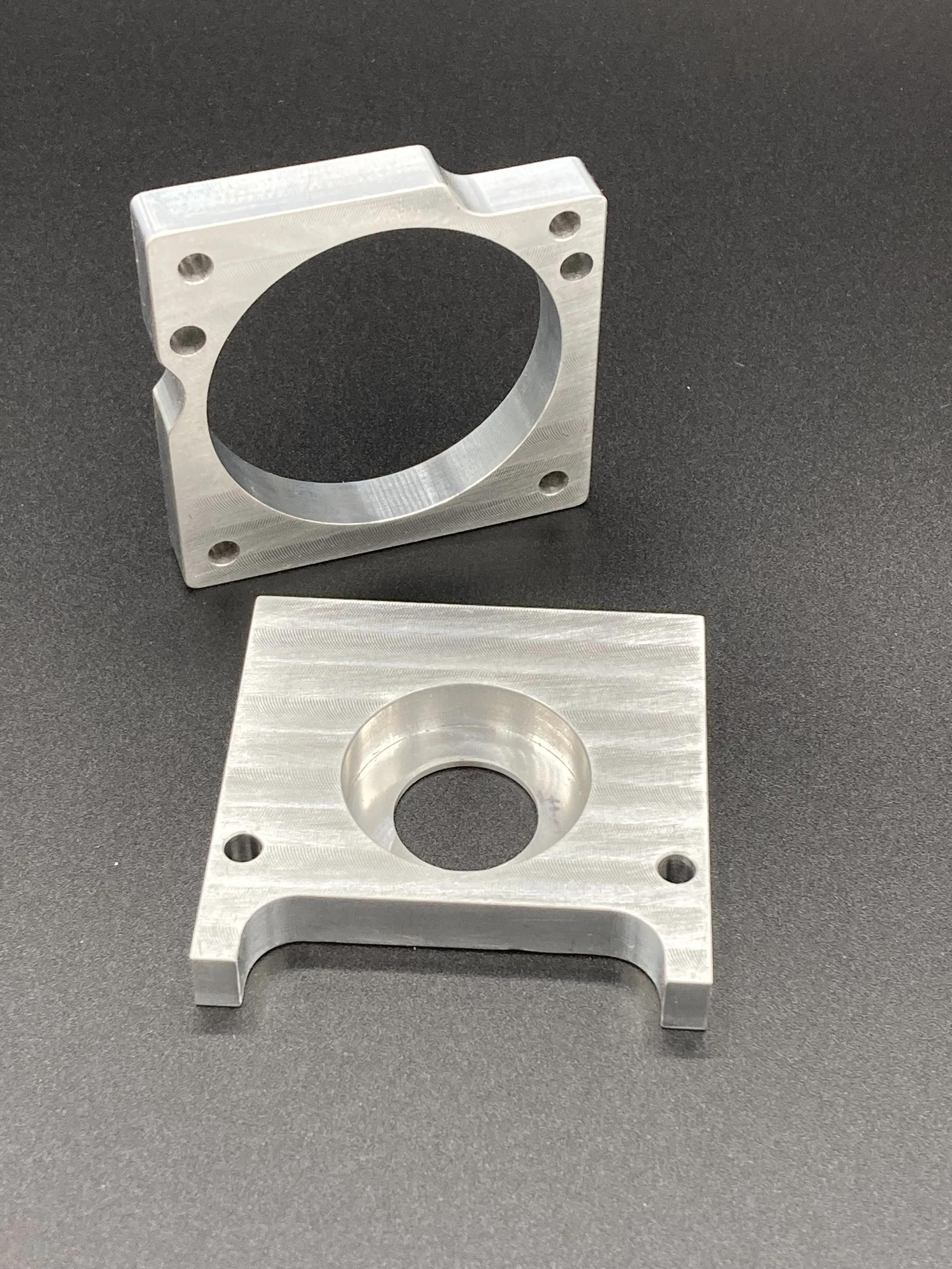

4:30 PM – The Final Inspection

Before the day ends, every completed part undergoes a meticulous inspection. Micrometers, calipers, and laser measurement tools confirm that each dimension matches the blueprint exactly. Only then is the part signed off and sent to shipping.

5:00 PM – Clocking Out, But Not Switching Off

The machines power down, but the work lingers in the machinist’s mind. Tomorrow will bring new blueprints, new challenges, and new opportunities to turn raw metal into something extraordinary.

Precision machining isn’t just a job, it’s a craft. It’s the art of making the invisible visible, of turning fractions of a millimeter into the difference between failure and perfection.

In the end, a machinist’s day is a blend of science, skill, and patience. It’s a profession where the smallest details matter most, and where every part that leaves the shop carries the quiet pride of the person who made it.

Question for you: If you had to work with tolerances so tight that a human hair would be considered too thick, how would you handle the pressure?