How to Advance Your Machining Career Without Leaving the Shop Floor

Career Growth Strategies for Those Who Prefer Hands-On Work

Many machinists prefer to stay on the shop floor, where their skill and craftsmanship transform raw material into precision parts. Remaining in a hands-on role does not limit career growth; you can continue to advance, increase your earnings, and gain respect without stepping away from the machines.

This article outlines specific ways you can grow your machining career while remaining deeply involved in hands-on work.

1. Master Advanced Machining Techniques

If you want to stand out in your shop, focus on deepening your technical expertise. For example, learning multi-axis machining, such as 4-axis and 5-axis work as it can give you access to more complex and higher-paying projects. Developing specialized skills like these makes you more valuable and harder to replace.

2. Become the Go-To Problem Solver

Machine shops depend on meeting deadlines, so minimizing downtime is crucial. When you can troubleshoot issues, optimize programs, or quickly improve accuracy, you become an essential member of the team. Volunteering to help with challenging jobs demonstrates your initiative and reliability.

3. Invest in Continuous Learning

You do not have to leave the shop to continue learning and growing. Seek certifications, such as NIMS or training from machine manufacturers like Haas, Mazak, or Okuma. Take advantage of online courses from providers like Tooling U-SME and LinkedIn Learning, which offer focused and flexible lessons. Attending trade shows and seminars, including IMTS, EASTEC, and local expos as it can also expose you to new tools and techniques.

4. Build Your Reputation Inside the Shop

Advancing your career is not just about your technical skill; how others perceive you is important too. Mentoring junior machinists is a great way to demonstrate leadership and share your knowledge without leaving the shop floor.

5. Take Ownership of Quality and Efficiency

Machinists who approach their work with a process engineer’s mindset while still running machines, often experience faster career growth. Taking the initiative to suggest fixture improvements, for example, shows your commitment to enhancing both quality and efficiency.

6. Explore Side Projects and Special Assignments

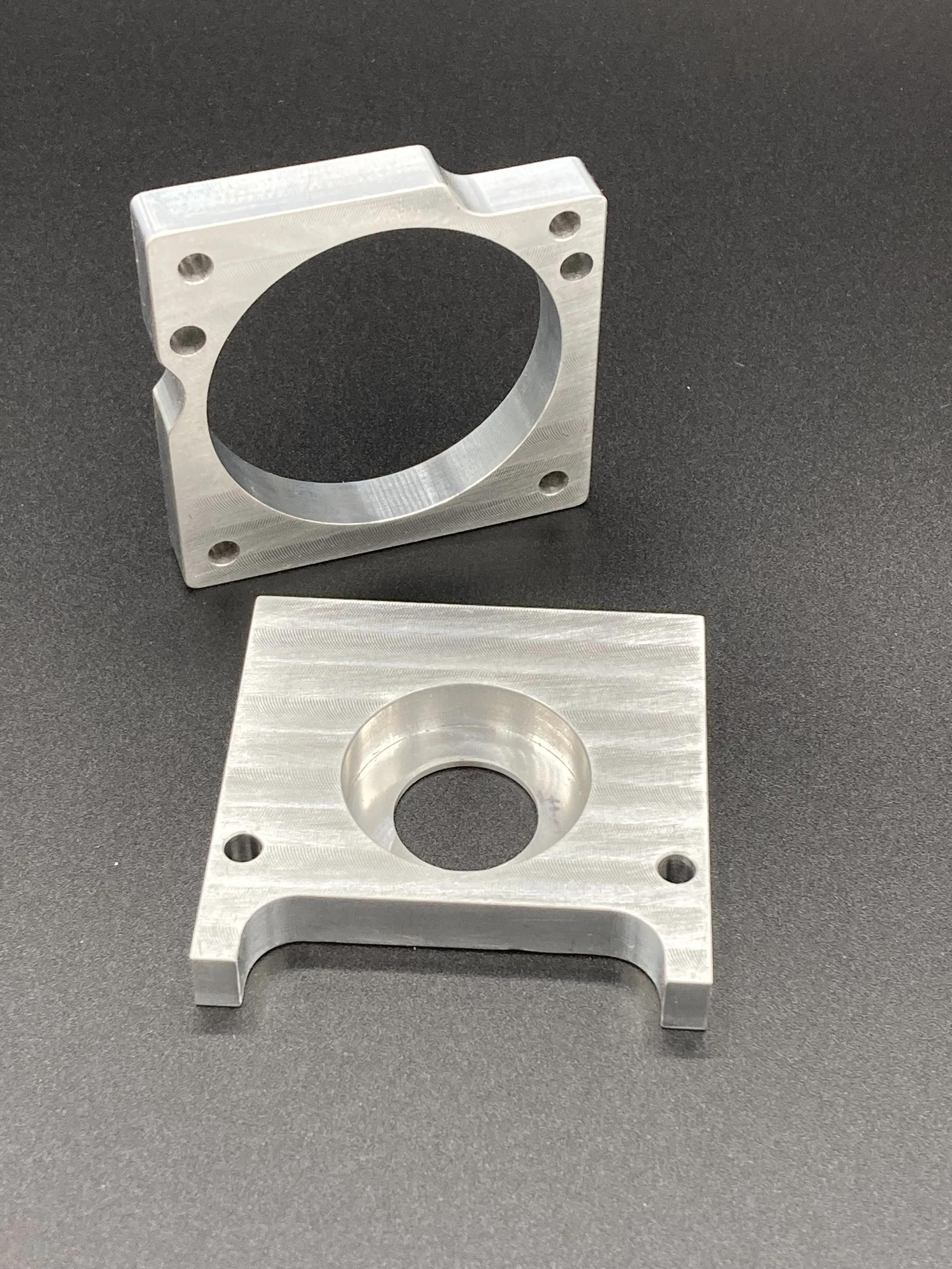

Sometimes, the best opportunities for advancement come from stepping slightly outside your regular routine. Taking on side projects such as prototype work for R&D teams allows you to expand your skills and visibility without leaving the shop floor.

7. Network Without Leaving the Shop

Networking is not limited to office workers. Building relationships with vendors, tooling representatives, and service technicians can open new doors and provide valuable industry connections.

Final Thoughts

You can move your machining career forward by honing your skills, solving problems, and building your reputation, all while remaining on the shop floor and staying true to hands-on work rather than moving into management.