Machining Myths Busted: Separating Fact from Fiction

Debunking common misconceptions about the trade.

Machining Myths Busted: Separating Fact from Fiction

Machining is one of those trades that often sits in the shadows of public awareness, until you need a precision part, a custom prototype, or a component that simply must work. Yet, despite its critical role in manufacturing, machining is surrounded by myths that can distort how people view the profession. These misconceptions can discourage new talent, mislead customers, and even slow innovation.

In this article, we’ll bust some of the most common machining myths and set the record straight.

Myth #1: Machining Is an Outdated Trade

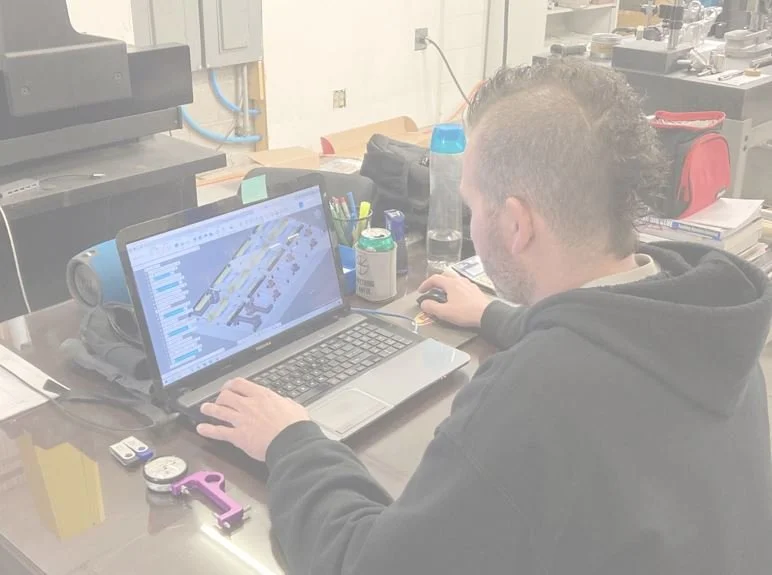

The Reality: Far from being a relic of the past, machining is at the cutting edge of technology. Modern CNC (Computer Numerical Control) machines integrate AI-driven programming, 5-axis capabilities, and precision. Aerospace, medical, and renewable energy industries rely on machining for components.

Machining today is as much about mastering software and automation as it is about handling metal.

Myth #2: Anyone Can Do It Without Much Training

The Reality: While entry-level tasks can be learned quickly, becoming a skilled machinist takes years of practice and problem-solving. Machinists must understand material science, tool geometry, CAD/CAM programming, and quality control. The trade blends craftsmanship with engineering, making it both intellectually and technically demanding.

Myth #3: Machining Is Only About Metal

The Reality: Metals like steel, aluminum, and titanium are common, but machinists also work with plastics, composites, ceramics, and exotic alloys. Each material has its own quirks like cutting speeds, heat resistance, and chip formation, that require specialized knowledge.

Myth #4: CNC Machines Do All the Work

The Reality: CNC machines are powerful tools, but they don’t think for themselves. A machinist must program the toolpaths, select the right tooling, and adjust for real-world variables like tool wear or material inconsistencies. Without human expertise, even the most advanced CNC can produce expensive scrap.

Myth #5: Machining Is a “Dirty” Job

The Reality: While older machine shops might have been oily and noisy, modern facilities often look more like tech labs, clean, organized, and climate-controlled. Safety standards, coolant systems, and dust extraction have transformed the work environment.

Why Busting These Myths Matters

Misconceptions about machining can:

Discourage young people from entering a high-demand, well-paying career.

Undervalue the skill and precision required in the trade.

Slow adoption of innovation by framing machining as “old tech.”

By separating fact from fiction, we can better appreciate machining as a modern, evolving, and essential part of the manufacturing ecosystem.

Final Thought:

Machining isn’t just about cutting metal, it’s about solving problems, pushing the limits of precision, and shaping the physical world.