A Beginner’s Guide to Starting Your Career in Machining

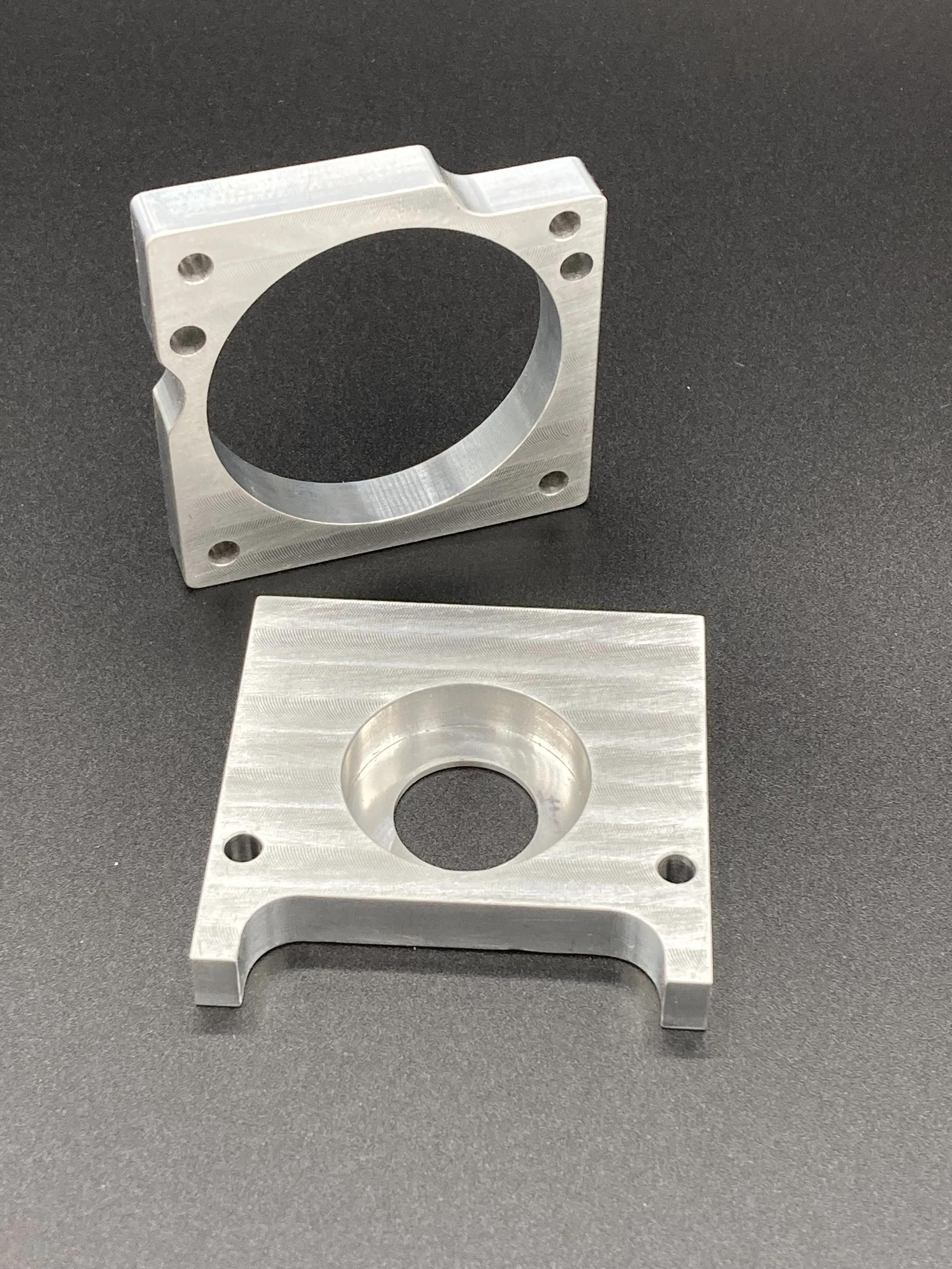

If you’ve ever marveled at the precision of an airplane engine, the smooth glide of a medical device, or the intricate parts inside your car, you’ve already seen the handiwork of machinists. Machining is the art and science of shaping raw materials, often metal or plastic into precise components that power our modern world.

This guide will walk you through what machining is, why it’s a promising career path, and how to take your first steps into this skilled trade.

Why Choose a Career in Machining?

Machining is more than just operating machines, it’s about problem-solving, precision, and craftsmanship. Here’s why it’s worth considering:

High Demand: Skilled machinists are in short supply, making this a stable career choice.

Step 1: Understand the Role of a Machinist

A machinist uses tools such as lathes, milling machines, and CNC (Computer Numerical Control) equipment to create parts with exact specifications. The work involves:

Reading blueprints and technical drawings

Step 2: Get the Right Education and Training

While some machinists learn entirely on the job, most start with a combination of formal training and hands-on experience.

Common pathways include:

Technical or Trade School: Many community colleges offer machining or manufacturing technology programs.

Step 3: Build Your Skills

Machining requires both technical and soft skills:

Technical Skills: Precision measurement, CNC programming, tool setup, and material knowledge.

Pro Tip: Even if you start with manual machines, learning CNC programming will open more career opportunities.

Step 4: Gain Experience

Your first job might be as a machine operator or shop assistant. Use this time to:

Learn different machine types and processes.

Step 5: Advance Your Career

Once you’ve mastered the basics, you can specialize or move into higher-paying roles:

CNC Programmer

Continuing education and certifications can help you climb the ladder faster.

Final Thoughts

Starting a career in machining is like learning a craft that blends tradition with cutting-edge technology. It’s a field where skill, precision, and creativity meet, and where your work can literally keep the world moving.

So, if you’re ready to shape the future one part at a time, the path is clear: learn the fundamentals, get hands-on experience, and never stop improving.

What’s the first step you’ll take toward becoming a machinist, signing up for a class, visiting a local shop, or applying for an apprenticeship?