Amy Vasey is an Automation Design Engineer at HellermannTyton. She has been with the company for 20 years and recently helped introduce and implement 3D printing in their Automation department.

The product development group at HellermannTyton, familiar with additive manufacturing technology, approached Amy’s team, asking if they’d ever considered 3D printing some of their many aluminum parts.

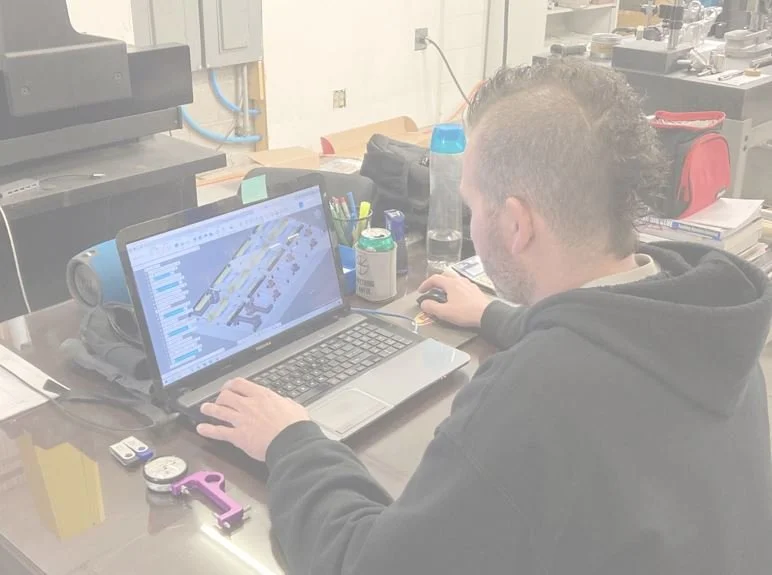

At the time, Vasey and her team weren’t familiar with the technology or where to start. “The product development team was really good at pushing us to start with something small, and that’s what we did.”